Your Ultimate tensile stress symbol images are ready in this website. Ultimate tensile stress symbol are a topic that is being searched for and liked by netizens now. You can Get the Ultimate tensile stress symbol files here. Get all free photos.

If you’re looking for ultimate tensile stress symbol pictures information linked to the ultimate tensile stress symbol keyword, you have visit the right site. Our website always gives you suggestions for seeing the maximum quality video and picture content, please kindly hunt and locate more enlightening video articles and images that match your interests.

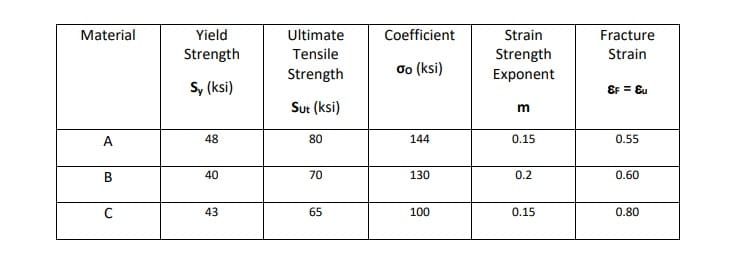

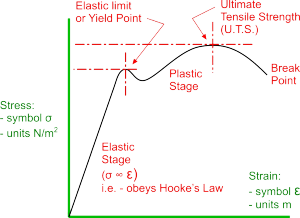

Ultimate Tensile Stress Symbol. The endurance limit also known as fatigue limit is a stress level below which a material has an infinite life. Figure 2 Tensile and compressive forces are called DIRECT FORCES. It is defined as the maximum stress that a material can withstand when a force is applied. It is the ability of a material to resist tearing due to tension.

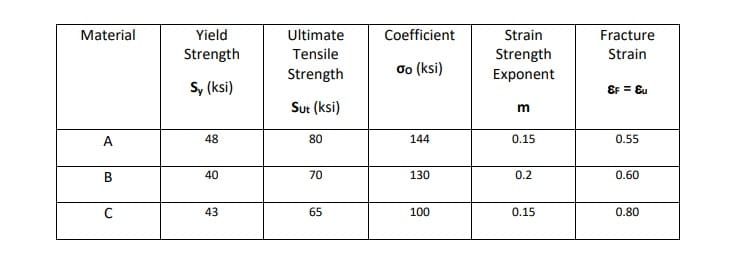

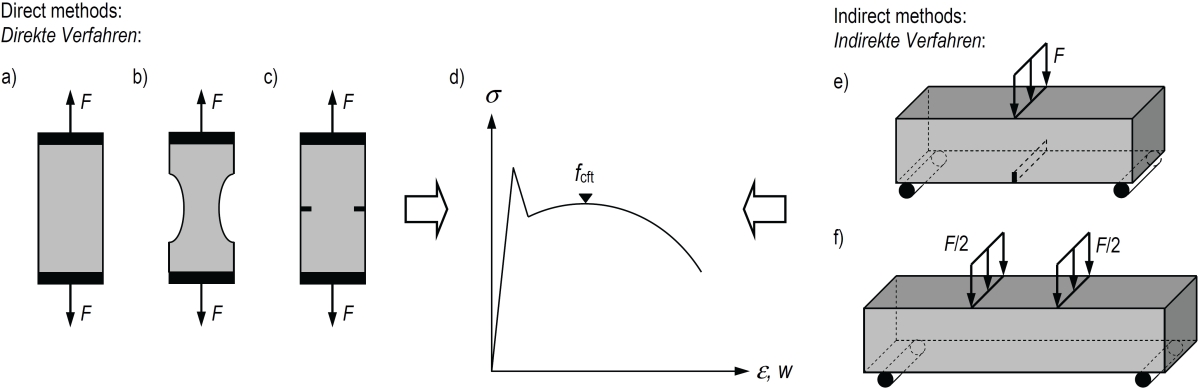

Material Coefficient Yield Strength Ultimate Tensile Chegg Com From chegg.com

Material Coefficient Yield Strength Ultimate Tensile Chegg Com From chegg.com

The tensile stress σ that develops when an external stretching force F is applied on an object is given by σ FA where A is the cross sectional area of the object. This is a small quantity in most fields of engineering so we. In the US the UTS is often expressed in pounds per square inch or psi. Stress level lesser than the maximumultimate stress which is called the breaking stress. R m max. Symbol ultimate tensile strength tags.

σ normal stress parallel to the axis of the weld σ normal stress perpendicular to the axis of the weld τ shear stress τ shear stress in the critical plane of the throat parallel to the weld axis τ shear stress in the critical plane of the weld perpendicular to the weld axis η stiffness modification coefficient.

Infinite life is commonly considered to be 1 million cycles. Symbol for allowable stress in design codes psi ksi kPa MPa Fa allowable axial stress psi ksi kPa MPa Fb allowable bending stress psi ksi kPa MPa F b allowable bending stress for combined stress for wood design psi ksi kPa MPa Fc. Symbol τ is used to represent shear stress. To show the applied force and direction of the application area subscripts are used with the symbol τ as τ ij. Tensile strength is defined as a measurement of stress which in turn is measured as force per unit area. σ normal stress parallel to the axis of the weld σ normal stress perpendicular to the axis of the weld τ shear stress τ shear stress in the critical plane of the throat parallel to the weld axis τ shear stress in the critical plane of the weld perpendicular to the weld axis η stiffness modification coefficient.

Source: chegg.com

Source: chegg.com

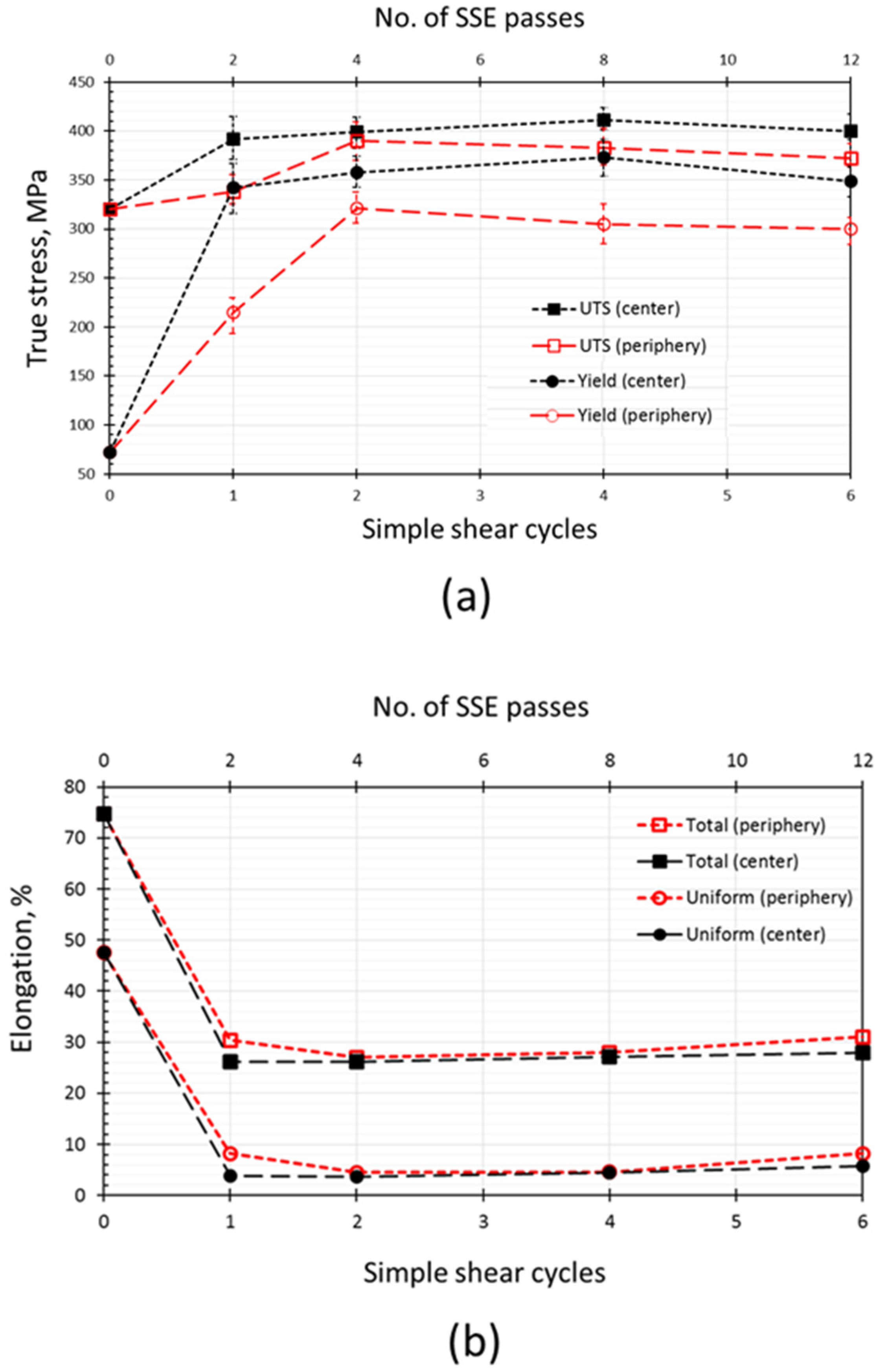

This parameter applies to all types of. The table below identifies the symbols and units used in the calculation of stress and strain. Symbol τ is used to represent shear stress. A Yield strength filled symbols and ultimate tensile strength open symbols as well as b uniform elongation filled symbols and elongation to. Tensile force F stress area N mm2 Tensile strength at rupture in cylindrical shank.

Source: wiki.dtonline.org

Source: wiki.dtonline.org

To show the applied force and direction of the application area subscripts are used with the symbol τ as τ ij. In the study of strength of materials tensile strength compressive strength and shear strength can be. Ultimate strength alone is explained here its purpose on this page is to show how it is related to the endurance limit. Tensile force F initial cross section of specimen N. For electrodes suitable for multi-run welding symbol 35 38 42 46 50 is used to indicated a minium yield strength of 355 Nmm 2 380 Nmm 420 Nmm 460 Nmm 2 or 500 Nmm respectively.

The tensile stress σ that develops when an external stretching force F is applied on an object is given by σ FA where A is the cross sectional area of the object. σ normal stress parallel to the axis of the weld σ normal stress perpendicular to the axis of the weld τ shear stress τ shear stress in the critical plane of the throat parallel to the weld axis τ shear stress in the critical plane of the weld perpendicular to the weld axis η stiffness modification coefficient. This parameter applies to all types of. Tensile force F initial cross section of specimen N. In the study of strength of materials tensile strength compressive strength and shear strength can be.

Source: mem50212.com

Source: mem50212.com

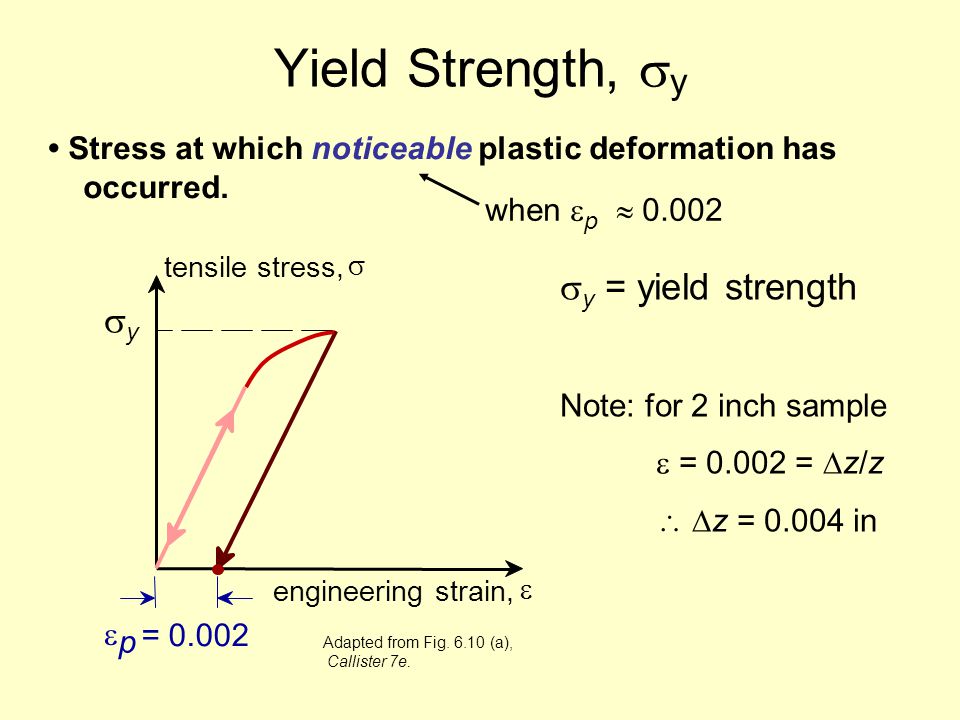

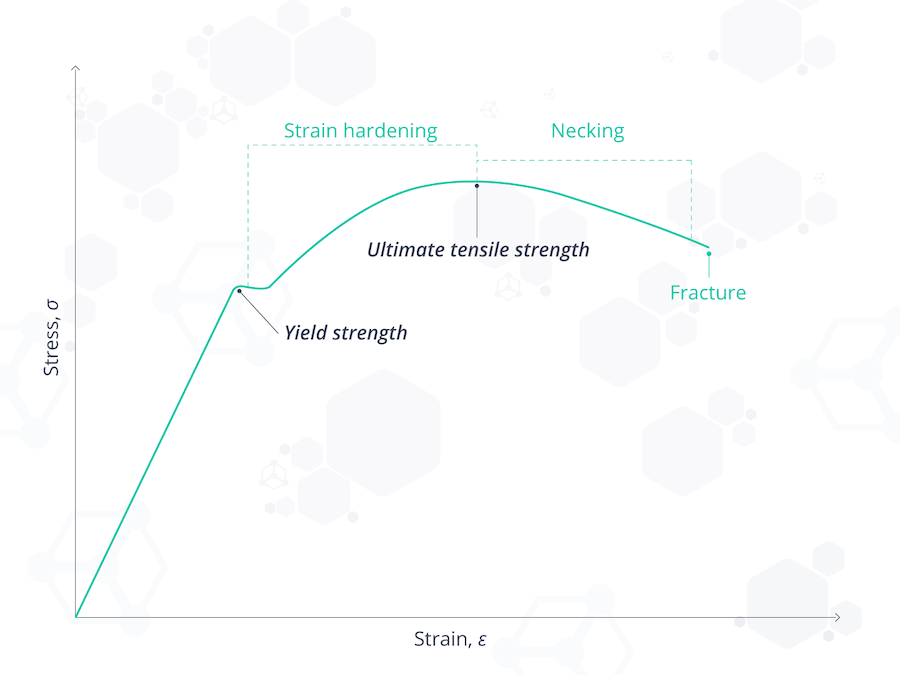

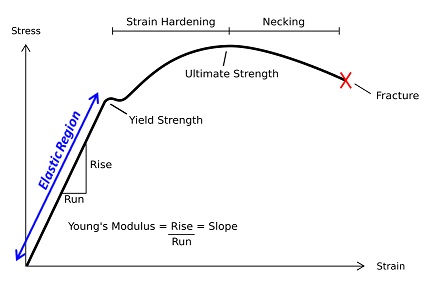

R m max. The ultimate tensile strength is the maximum on the engineering stress-strain curve. Stress is the force per unit area upon which it acts. 0 Symbol for impact properties of allweld metal Z A 0 2 3 4 5 6 RR Symbol for type of electrode covering. The tensile stress σ that develops when an external stretching force F is applied on an object is given by σ FA where A is the cross sectional area of the object.

Source: bossard.com

Source: bossard.com

Where γ C is the partial safety factor for concrete for the examined design state as specified in EN1992-1-1 2424 and the National Annex. The ultimate tensile strength is determined from uniaxial tests. Ultimate tensile strength is often shortened to tensile strength or even to the ultimate Ultimate tensile strength is often shortened to tensile strength or even to the ultimate. Stress ForceArea Nm2 or Pascals. Infinite life is commonly considered to be 1 million cycles.

Source: pinterest.com

Source: pinterest.com

It is defined as the maximum stress that a material can withstand when a force is applied. The symbol is called SIGMA NOTE ON UNITS The fundamental unit of stress is 1 Nm2 and this is called a Pascal. The tensile stress σ that develops when an external stretching force F is applied on an object is given by σ FA where A is the cross sectional area of the object. This is a small quantity in most fields of engineering so we. To measure elastic modulus the stress-strain curve is used.

Source: study.com

Source: study.com

Higher the load or tensile force higher the. The table below identifies the symbols and units used in the calculation of stress and strain. R m max. Youngs modulus of elasticity. The endurance limit also known as fatigue limit is a stress level below which a material has an infinite life.

Source: sciencedirect.com

Source: sciencedirect.com

A tensile force makes the body longer. The tensile stress σ that develops when an external stretching force F is applied on an object is given by σ FA where A is the cross sectional area of the object. The SI unit of UTS is Pascal or Pa. In the US the UTS is often expressed in pounds per square inch or psi. When the materials are pushed beyond UTS they experience the cracking.

When the materials are pushed beyond UTS they experience the cracking. Stress level lesser than the maximumultimate stress which is called the breaking stress. When the materials are pushed beyond UTS they experience the cracking. Infinite life is commonly considered to be 1 million cycles. The max stress is taken 40 less when loaded for more than 10 million load cycles.

Source: researchgate.net

Source: researchgate.net

Stress level lesser than the maximumultimate stress which is called the breaking stress. Tensile strength is defined as a measurement of stress which in turn is measured as force per unit area. The SI unit of UTS is Pascal or Pa. It does represent material characteristic but the engineering stress strain curve does. This value is approximately 15 lesser than the ultimate strength.

Source: bft-international.com

Source: bft-international.com

Tensile strength is defined as a measurement of stress which in turn is measured as force per unit area. For electrodes suitable for multi-run welding symbol 35 38 42 46 50 is used to indicated a minium yield strength of 355 Nmm 2 380 Nmm 420 Nmm 460 Nmm 2 or 500 Nmm respectively. Where i represent the direction of the surface plane on which it is being applied perpendicular to the surface and j represents the applied forces direction. The tensile stress σ that develops when an external stretching force F is applied on an object is given by σ FA where A is the cross sectional area of the object. It is the ability of a material to resist tearing due to tension.

Source: slideplayer.com

Source: slideplayer.com

Ultimate strength alone is explained here its purpose on this page is to show how it is related to the endurance limit. The capacity of a material or structure to withstand loads tending to elongate is known as ultimate tensile strength UTS. A tensile force makes the body longer. Stress ForceArea Nm2 or Pascals. For stainless steel 14310 the tensile strength is 15 less according EN 10270-3-NS.

The max bending stress is taken 07Rm the max torsional stress 04Rm when statically loaded. Nm² and Nmm². The SI unit of UTS is Pascal or Pa. Ultimate tensile strength unit. Figure 2 Tensile and compressive forces are called DIRECT FORCES.

Source: leonghuat.com

Source: leonghuat.com

R m max. Where γ C is the partial safety factor for concrete for the examined design state as specified in EN1992-1-1 2424 and the National Annex. To show the applied force and direction of the application area subscripts are used with the symbol τ as τ ij. Tensile strength at rupture in thread. Ultimate strength alone is explained here its purpose on this page is to show how it is related to the endurance limit.

Source: matmatch.com

Source: matmatch.com

The tensile stress σ that develops when an external stretching force F is applied on an object is given by σ FA where A is the cross sectional area of the object. Rockwell hardness in relation to compressive strength yield each subsequent time brings it closer to its ultimate strength yield strength vs tensile strength 800x400jpg Yield Point Related Keywords Suggestions Yield Point Long Tail Tensile Strength Related Keywords Suggestions Tensile Strength Tensile. It does represent material characteristic but the engineering stress strain curve does. For stainless steel 14310 the tensile strength is 15 less according EN 10270-3-NS. The capacity of a material or structure to withstand loads tending to elongate is known as ultimate tensile strength UTS.

Source: pediaa.com

Source: pediaa.com

Ultimate tensile strength unit. The coefficient α ct takes into account long term effects on the tensile strength and of unfavorable effects. The SI unit of UTS is Pascal or Pa. The ultimate tensile strength is the maximum on the engineering stress-strain curve. Therefore the SI unit of measuring tensile stress is Nm -2 or Pa.

Source: toppr.com

Source: toppr.com

Infinite life is commonly considered to be 1 million cycles. Youngs modulus of elasticity. The tensile stress σ that develops when an external stretching force F is applied on an object is given by σ FA where A is the cross sectional area of the object. The max stress is taken 40 less when loaded for more than 10 million load cycles. Figure 2 Tensile and compressive forces are called DIRECT FORCES.

Source: mdpi.com

Source: mdpi.com

Where γ C is the partial safety factor for concrete for the examined design state as specified in EN1992-1-1 2424 and the National Annex. Therefore the SI unit of measuring tensile stress is Nm -2 or Pa. Exceptions are stainless steel screws A1 to A4 ISO 3506. Usually tensile stress is defined as the force per unit area and denoted by the symbol σ. 1Nmm² 10⁶Nm² 1MNm² And 1kNmm².

This site is an open community for users to share their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site good, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title ultimate tensile stress symbol by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.